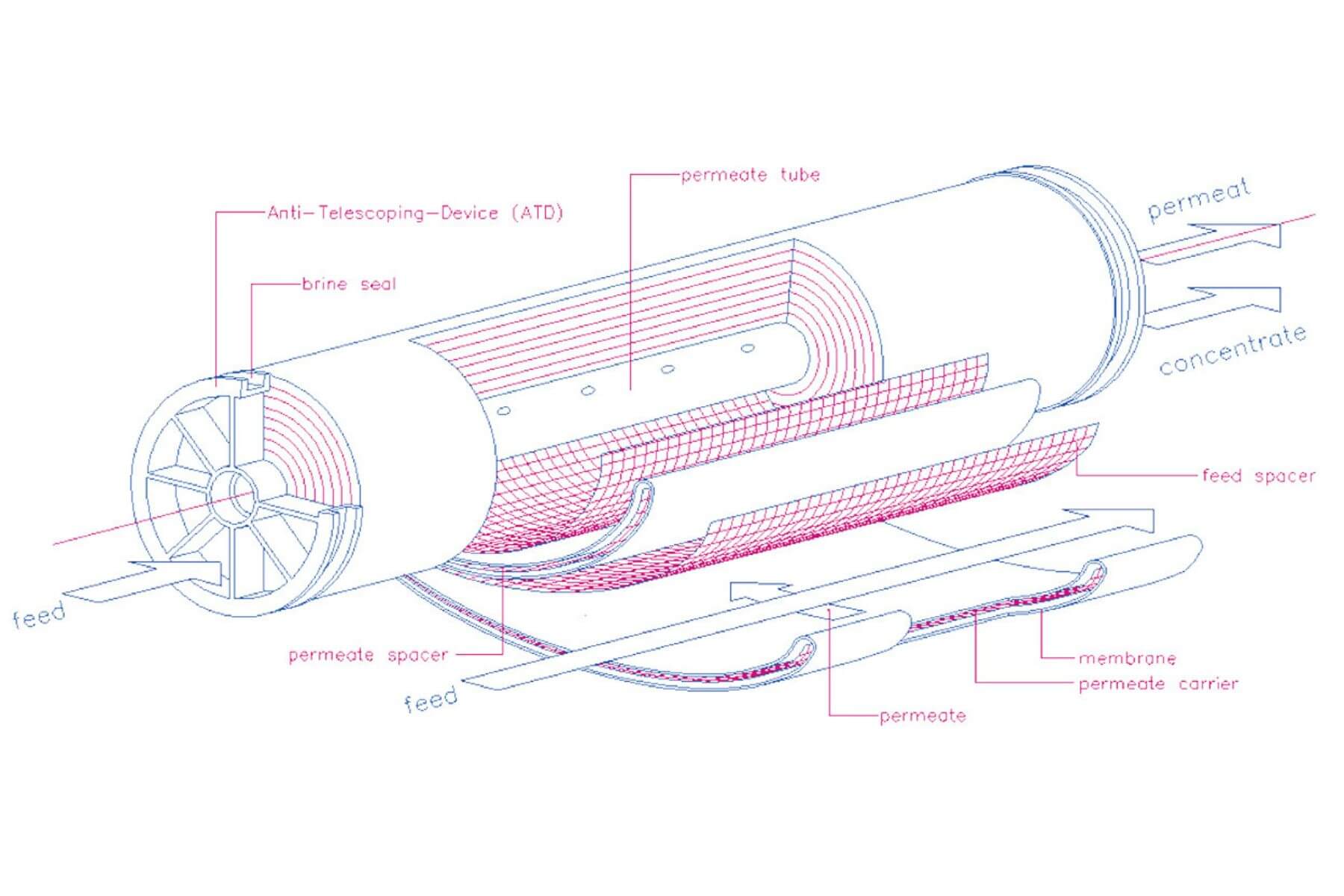

Spiral wound modules are particularly effective in nanofiltration as they offer an optimized membrane area in a compact design. These modules are designed to provide a high flow rate and improved separation efficiency, making them ideal for the removal of organic compounds, certain salts and pollutants. SpiraFlex nanofiltration modules are available with different NF membrane types and in various combinations of length and diameter.