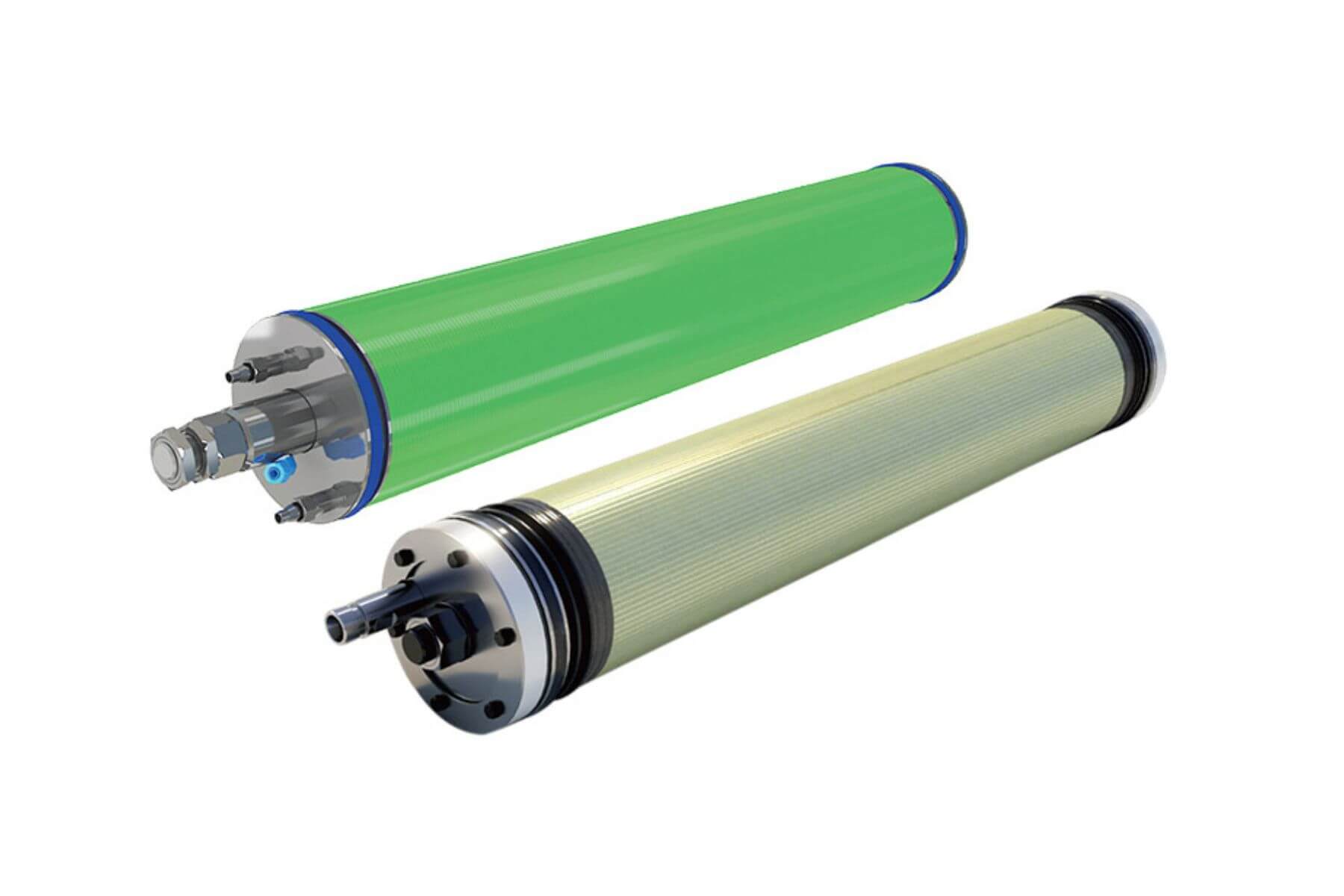

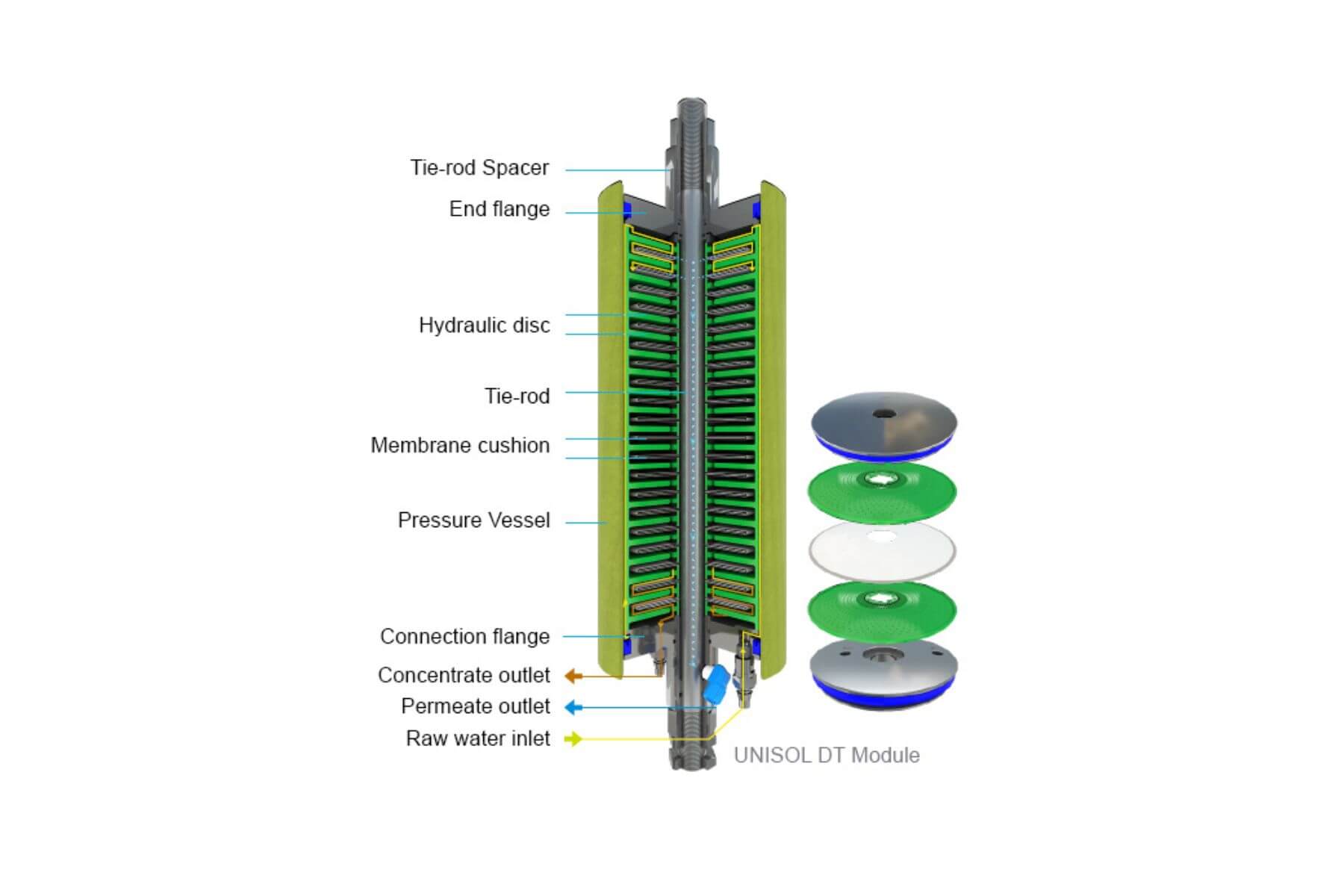

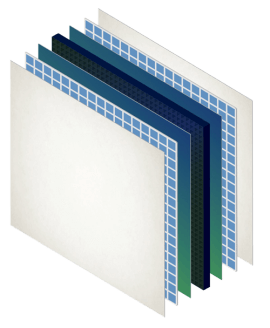

UNISOL’s cost-effective DT modules, based on decades of experience in industrial membrane technology, represent a breakthrough in desalination and liquid purification. These modules are designed for the efficient processing of streams with a high TDS value (Total Dissolved Solids) and offer versatile solutions for different separation requirements.